Medium Voltage Cables (1kV – 33kV)

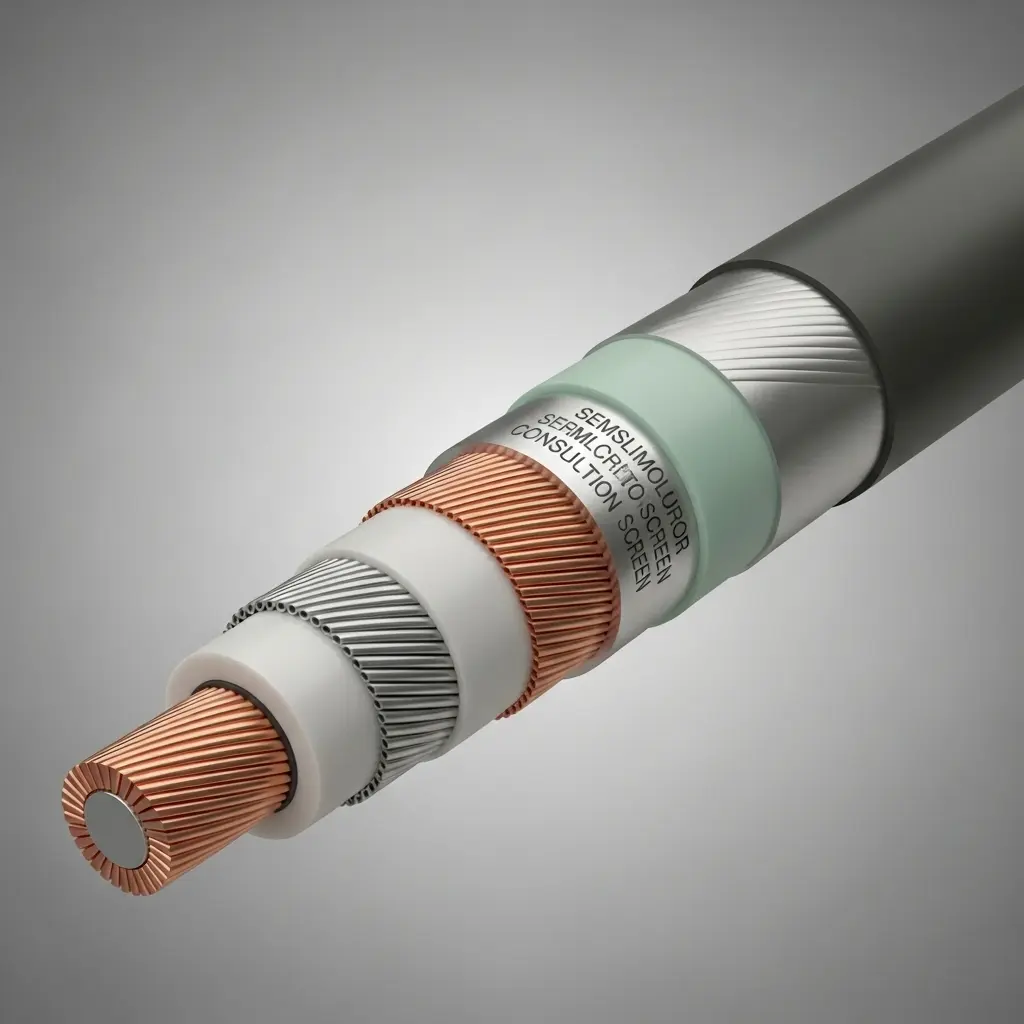

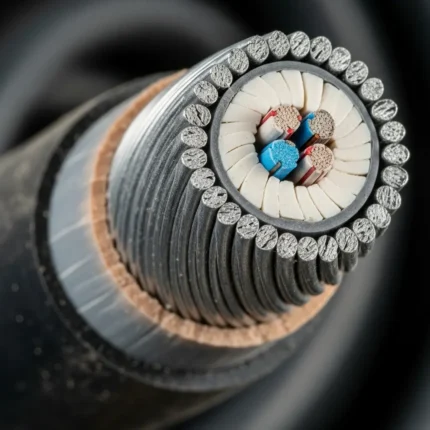

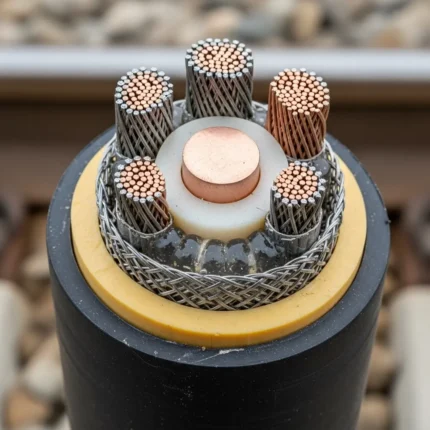

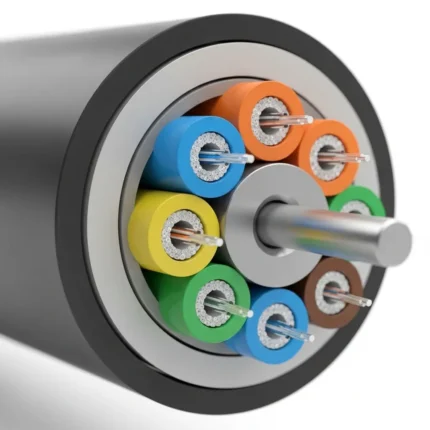

Medium voltage power cables designed for substation distribution networks and interconnection between 1kV and 33kV. Equipped with XLPE insulation, semi-conductive layers, and metallic screens for uniform electric field distribution, with optional mechanical protection via armouring. These cables provide stable electrical performance, continuous operating temperature up to 90°C or more, and reduced fault currents due to metallic screens and semi-conductive layers. Ideal for urban substation networks, connecting distribution stations, and underground or central duct installations.

Medium voltage power cables designed for substation distribution networks and interconnection between 1kV and 33kV. Equipped with XLPE insulation, semi-conductive layers, and metallic screens for uniform electric field distribution, with optional mechanical protection via armouring. These cables provide stable electrical performance, continuous operating temperature up to 90°C or more, and reduced fault currents due to metallic screens and semi-conductive layers. Ideal for urban substation networks, connecting distribution stations, and underground or central duct installations.

| Property |

Typical Value |

|---|---|

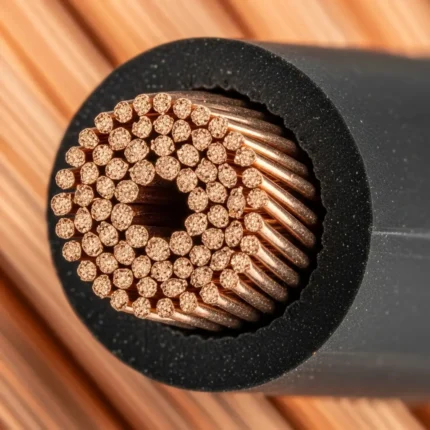

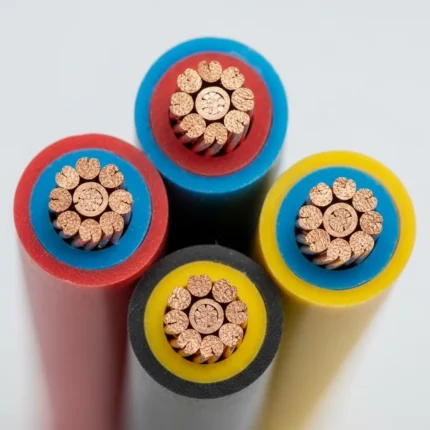

| Conductor |

Copper (Cu) or Aluminium (Al) stranded |

| Conductor Purity |

High |

| Insulation |

XLPE |

| Common Cross Sections |

50 — 240 mm²+ (depending on design) |

| Semi-Conductive Layers |

Present for electric field distribution |

| Rated Voltage |

3.3kV, 6.6kV, 11kV, 19/33kV |

| Metallic Screen/Shield |

Copper tape / Lead / Aluminum |

| Outer Sheath |

PVC / HDPE / LSZH |

| Optional Armour |

SWA |

| Operating Temperature |

90°C continuous or higher depending on design |

| Insulation Colors |

Multi-color for core identification |

| Additional Properties |

Fault current reduction, uniform electric field distribution |

- Urban substation distribution networks.

- Connecting distribution stations.

- Underground or central duct installations.

- IEC 60502-2, Nexans / Prysmian MV manuals.

- DC Hipot testing.

- Partial discharge tests.

- Tensile and bending tests for mechanical durability.

- Quality assurance according to Nexans Australia+1 standards.