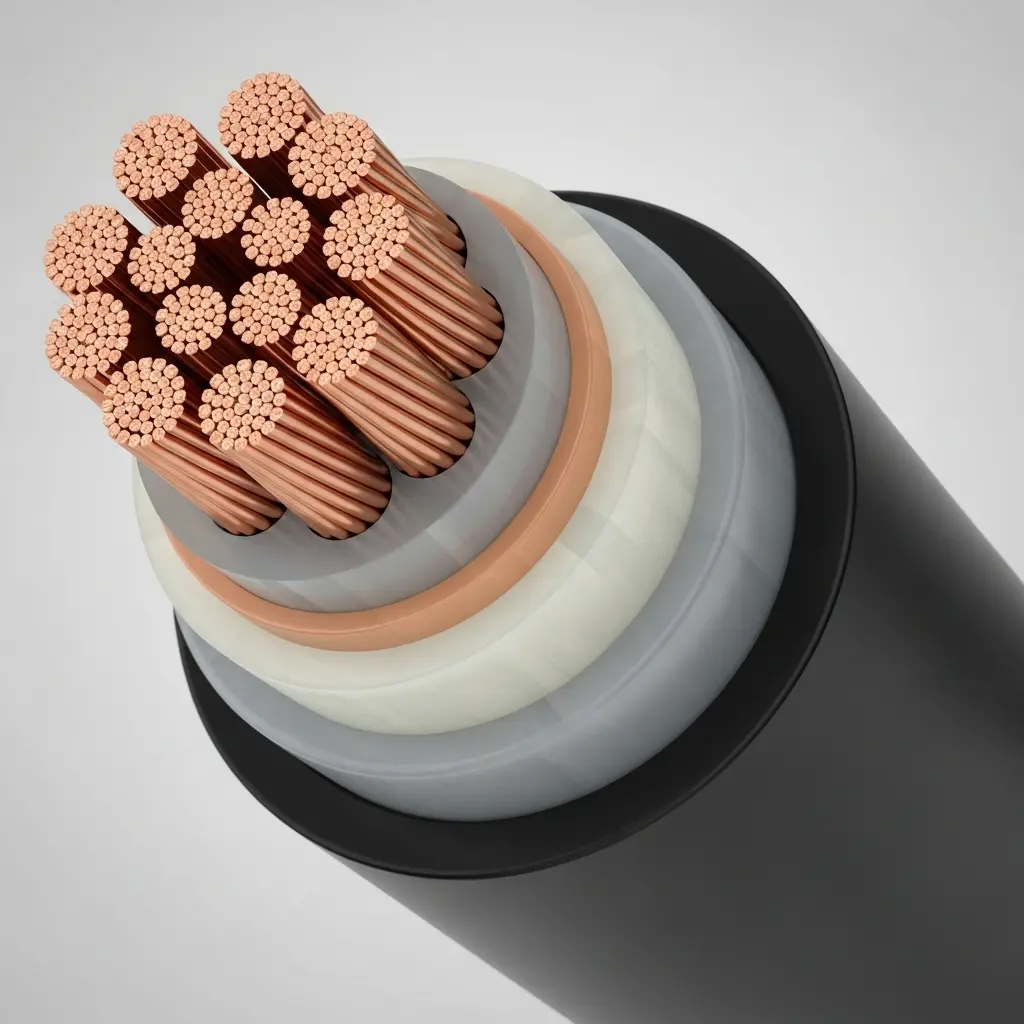

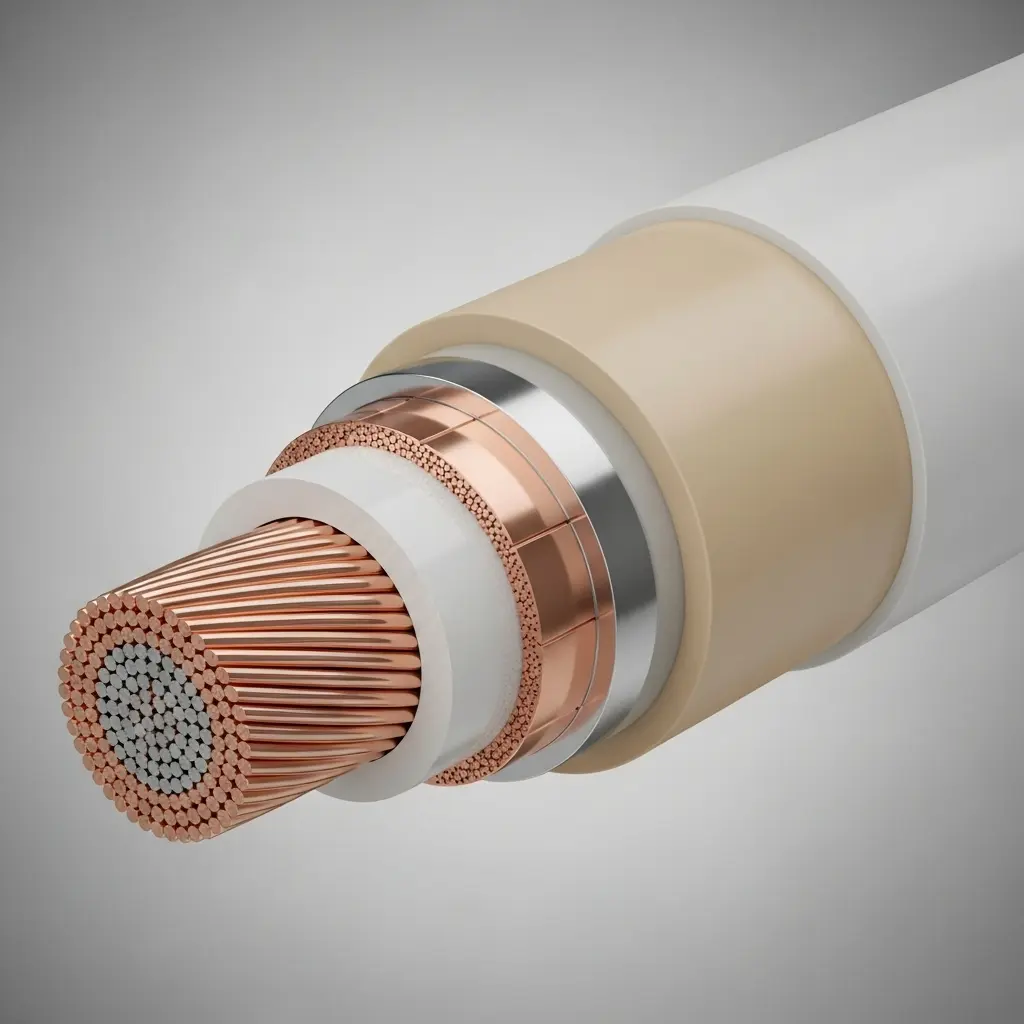

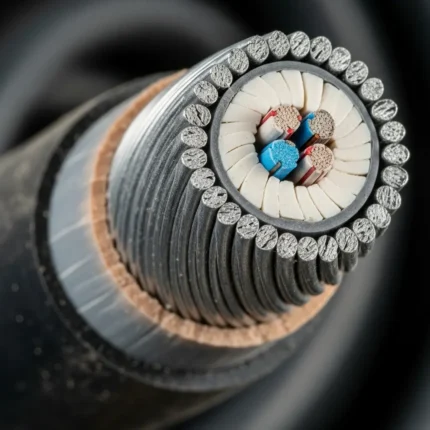

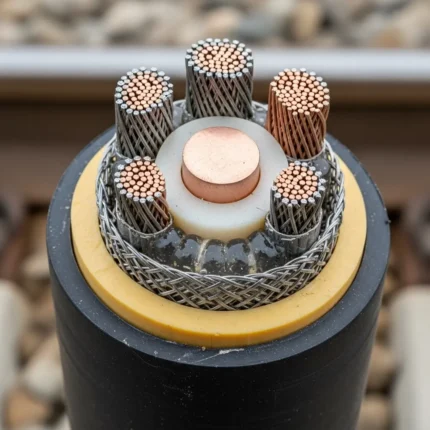

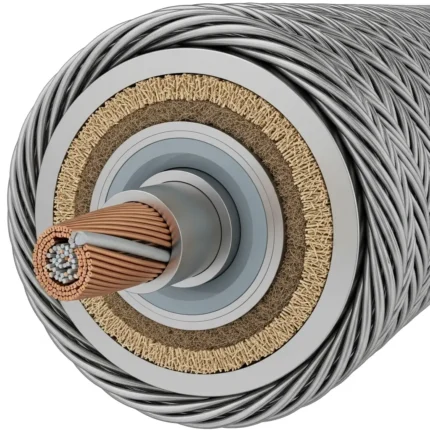

XLPE Insulated Copper Cables

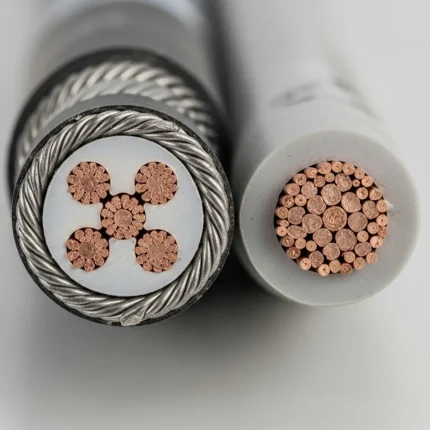

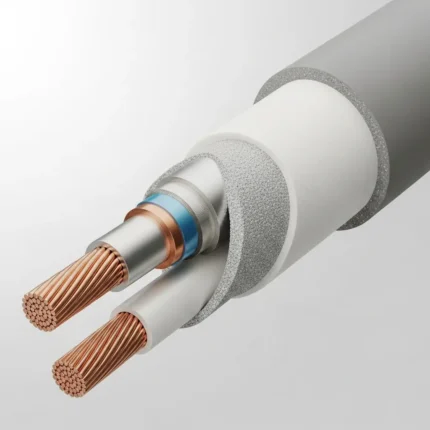

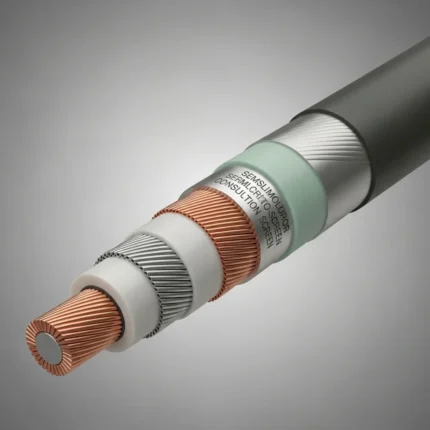

Copper wires and cables insulated with XLPE (Cross-Linked Polyethylene) provide superior thermal and electrical performance compared to conventional PVC wires. These cables withstand higher operating temperatures, feature lower electrical resistance, and offer higher current carrying capacity for the same cross-section. Ideal for residential, commercial, and industrial applications, including building and factory distribution systems, as well as power applications requiring high thermal performance. Available in various core configurations and cross-sections to suit diverse requirements.

Copper wires and cables insulated with XLPE (Cross-Linked Polyethylene) provide superior thermal and electrical performance compared to conventional PVC wires. These cables withstand higher operating temperatures, feature lower electrical resistance, and offer higher current carrying capacity for the same cross-section. Ideal for residential, commercial, and industrial applications, including building and factory distribution systems, as well as power applications requiring high thermal performance. Available in various core configurations and cross-sections to suit diverse requirements.

| Property |

Typical Value |

|---|---|

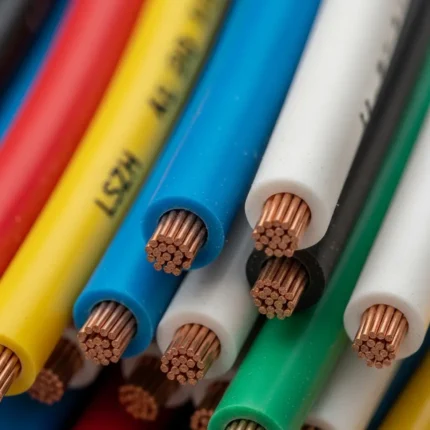

| Conductor |

Solid / Stranded Copper (Cu) |

| Conductor Purity |

High |

| Insulation |

XLPE |

| Common Cross Sections |

1.5 — 300 mm²+ |

| Rated Voltage |

0.6/1 kV or special MV ratings |

| Operating Temperature |

90°C continuous, higher depending on design |

| Number of Cores |

Single, multi-core |

| Insulation Colors |

Multi-color for core identification |

| Outer Sheath/Armour |

PVC or LSZH optional |

| Additional Properties |

Lower electrical resistance, higher current capacity |

- Electrical distribution systems in buildings and factories.

- Power cables for applications requiring higher thermal endurance.

- Underground installations or within multi-cable assemblies.

- Compliant with IEC / BS / LV catalogs (see Prysmian / Nexans manuals).

- Voltage and resistivity tests.

- Thermal aging tests to ensure continuous heat resistance.

- Quality assurance according to Prysmian Asean+1 standards.